The project is planned internationally at all three participating universities. You can realize the practical implementation of your project as part of an international exchange at one of the partner universities. You can also work on the at your own university.

Project topics:

WUST (Wroclaw, Poland)

1. “Weather Station Elements”

Goal: design and manufacture elements of a weather station (blades for a wind turbine, mechanical parts and housing) using FDM or DLP.

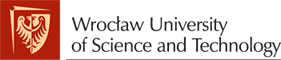

2. “Hybrid-material composite for actuation”

Goal: design, print and confirm the actuation of the 3D printed structures, which are composed of two or more different materials, as vibrating components for actuators in so-called 4D printing.

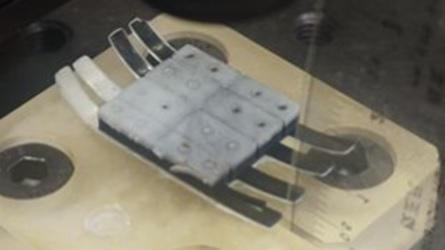

3. “Cell design of 3D printed cantilever”

Goal: design, print and confirm the selected mechanical properties of the 3D printed cantilevers for energy harvesters by different filling structures of the elementary 3DP cells.

4. “Design and Manufacturing of Microfluidics”

Goal: design and manufacture microfluidic structures in the form of valves, mixers, separators, and dispensers, which can be used in conducting different biological processes or chemical reactions.

UNIZA (Žilina, Slovakia)

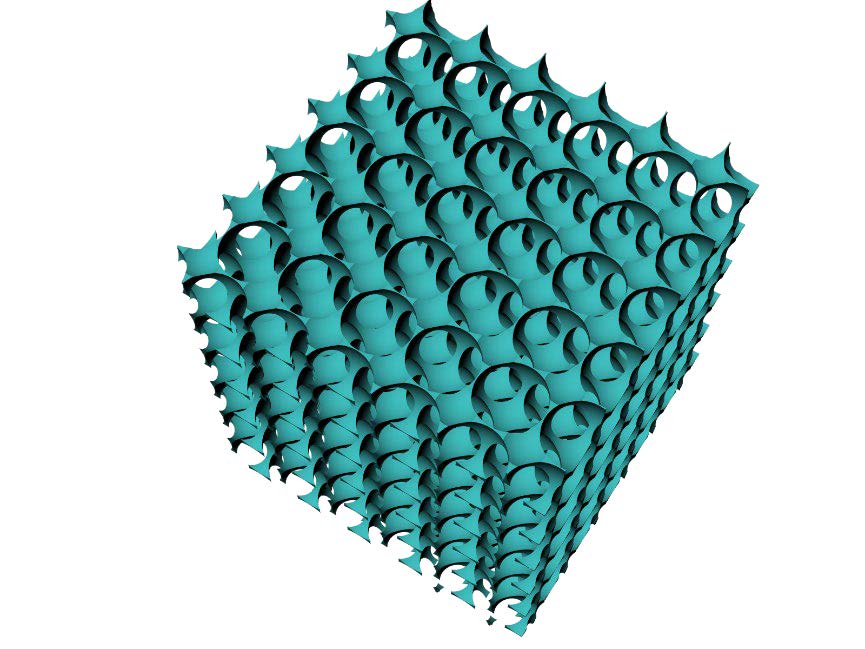

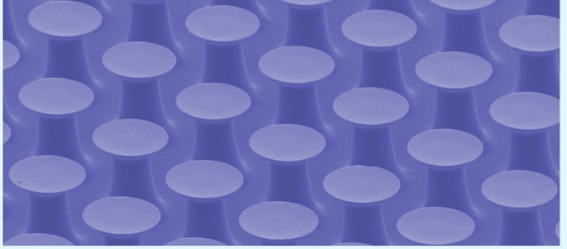

1. “Nature-inspired microstructures”

Goal: design and manufacture of natural photonic structures using 2PP, which have found important applications in switches, display devices, sensors.

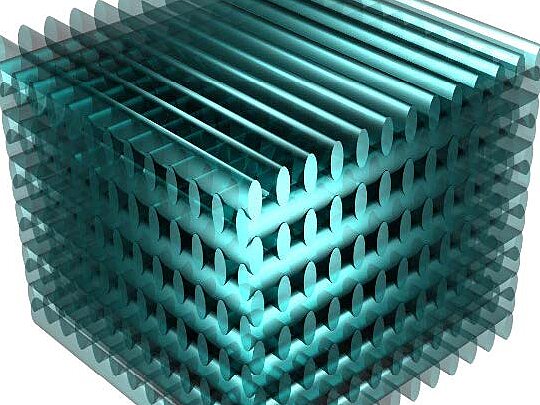

2. “Woodpile structure”

Goal: design and manufacture of photonic crystals structure with “woodpile” geometry using 2PP, which can be used e.g. as invisibility cloak with the exotic capability of making objects invisible in desired directions.

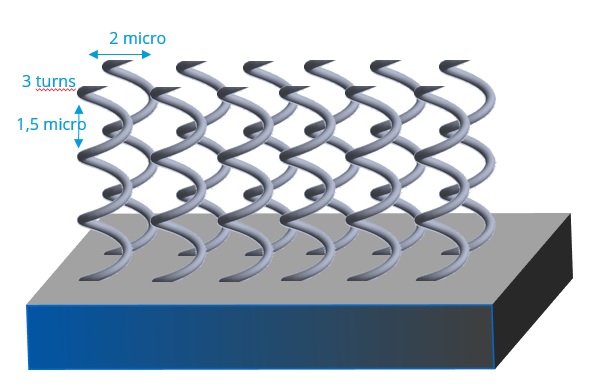

3. “Chiral microstructure”

Goal: design and manufacture of chiral plasmonic structures using 2PP, which can be used for ultrasensitive optical detection on biomolecules.

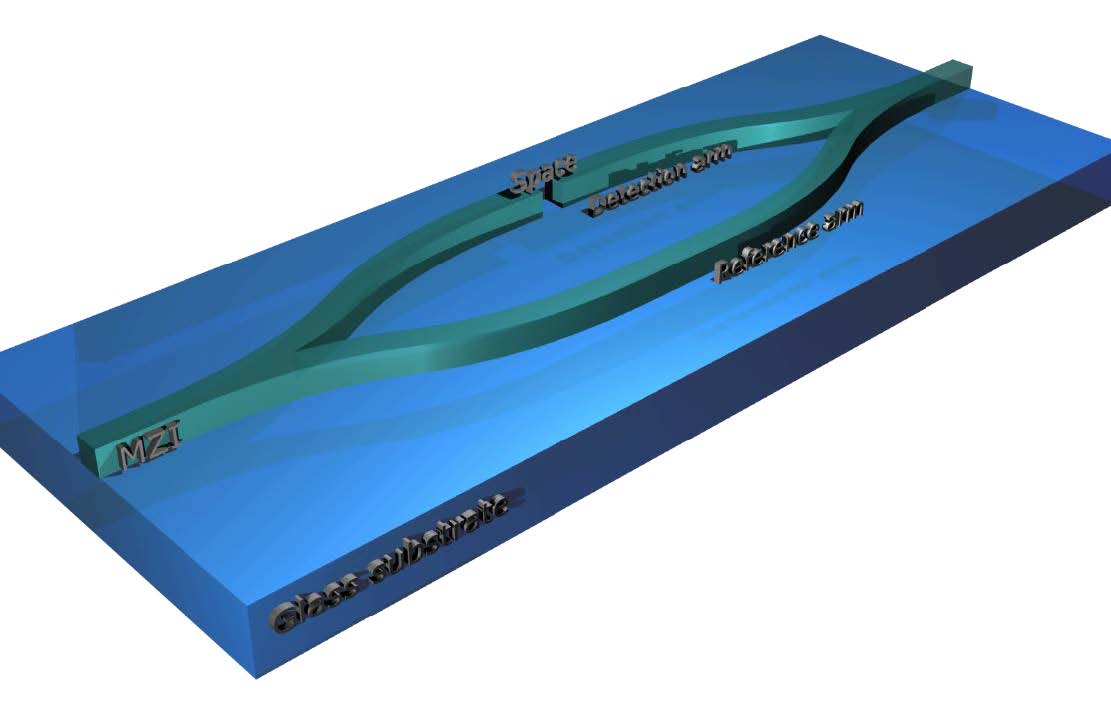

4. “On-chip Mach-Zehnder interferometer (MZI)”

Goal: design and manufacture of MZI structures, a photonic integrated circuit element as very sensitive device, which can be easily integrated on an optical chip using 2PP.

TUD (Dresden, Germany)

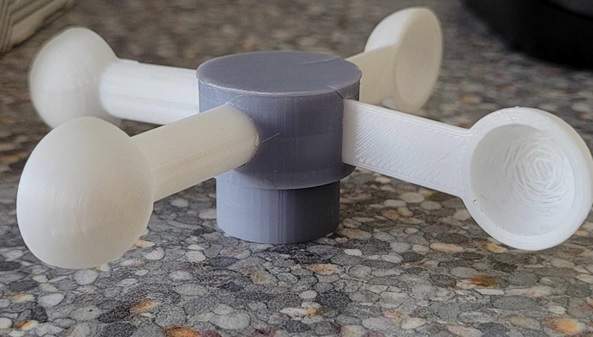

1. “Silicone Molding Form”

Goal: design and manufacture of a silicone molding form using DLP that allows sensors to be fully encapsulated, providing embedded package solution for various applications.

2. “Soft Gripper”

Goal: design and manufacture of so-called soft grippers with nature (gecko) inspired microstuctured surfaces using 2PP, that allow to pick up delicate samples.

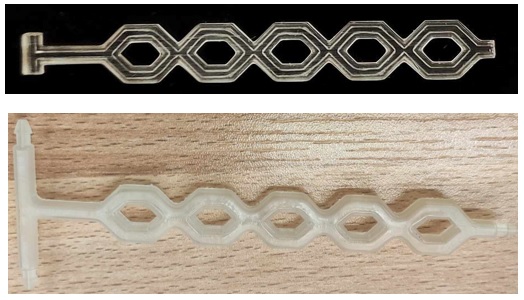

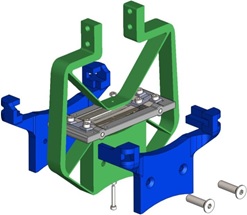

3. “Bistable Gripper”

Goal: design and manufacture of a gripper with two stable holding positions: an open state, where samples can be inserted, and a closed state.

4. “Gobo-Projector”

Goal: design and manufacture so-called Gobo-Projector that can transform the beam of a simple light source (LED or Laser) into a complex pattern.