The wide range of applications for 3D printing technologies makes them particularly attractive for research. It offers the opportunity to research and develop new materials, processes and applications. Furthermore, the integration of 3D printing into educational programs helps to inspire students for this forward-looking field and to let them exploit the potential of this new technology.

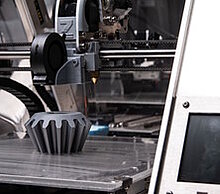

Fused Deposition Modeling (FDM)

Filament is fed from a large spool through a moving, heated printer extruder head, and is deposited on the growing work. The print head is moved under computer control to define the printed shape. Usually the head moves in two dimensions to deposit one horizontal plane, or layer, at a time; the work or the print head is then moved vertically by a small amount to begin a new layer.

Resolution is limited to few hundreds of µm by the used filament and also axis accuracy.

Stereolithography (SLA)

SLA is based on layer wise structuring of negative polymer resin using a UV pixel array projector. Substrate is placed against transparent bottom of resin tank through which the light is projected. Substrate is moved up after exposing one layer. Layer thickness can be as low as 50 µm and resolution is defined by pixel size which can be as low as few µm. This process is often used for embedding.

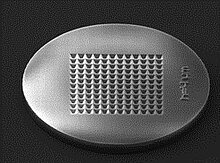

Two-photon polymerization (2PP)

Probability of 2PP is proportional to square of light intensity compared just intensity for UV absorption. Thus a negative polymer resin is only exposed inside the focal volume of a focused near infrared laser. This so called voxel, can be less than 1µm high and few hundred nm in diameter. Structure is formed by moving laser beam through the resin using piezos and galvanic mirror. This allows for arbitrary 3D-structures. These are highly interesting for applications in micro optics, fluidics, biology. The process is also often used to create imprinting masters, such as the negative pyramids in the image.

Inkjet Printing

Inkjet printing is similar to the well-known office printers, except that special dielectric and conductive inks can be used. The printing is done using small drops that are applied to the desired positions on the substrate. With this technology, entire circuits can be produced by printing. The SuperinkJet is a special variant that enables line widths down to a few µm.